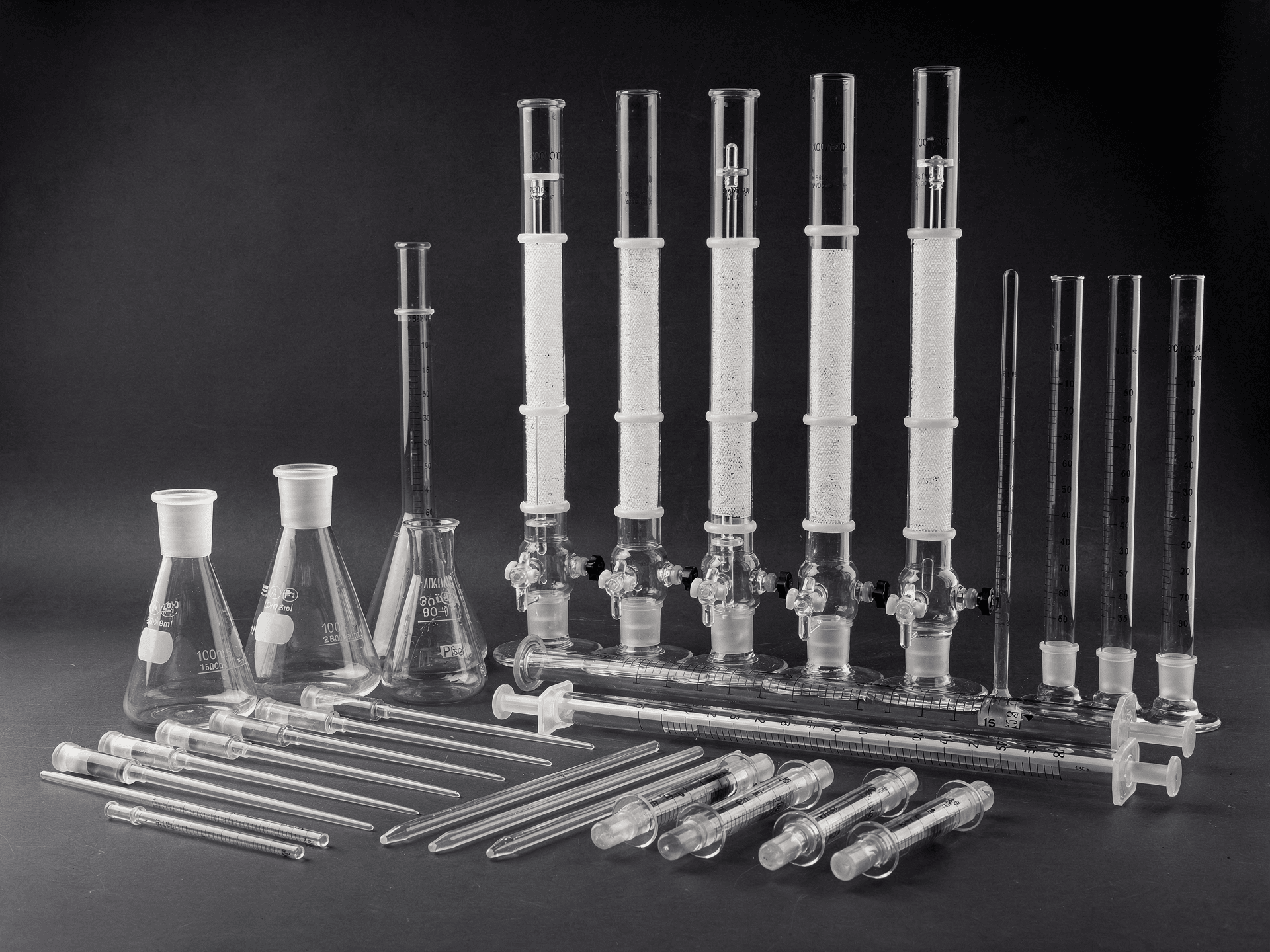

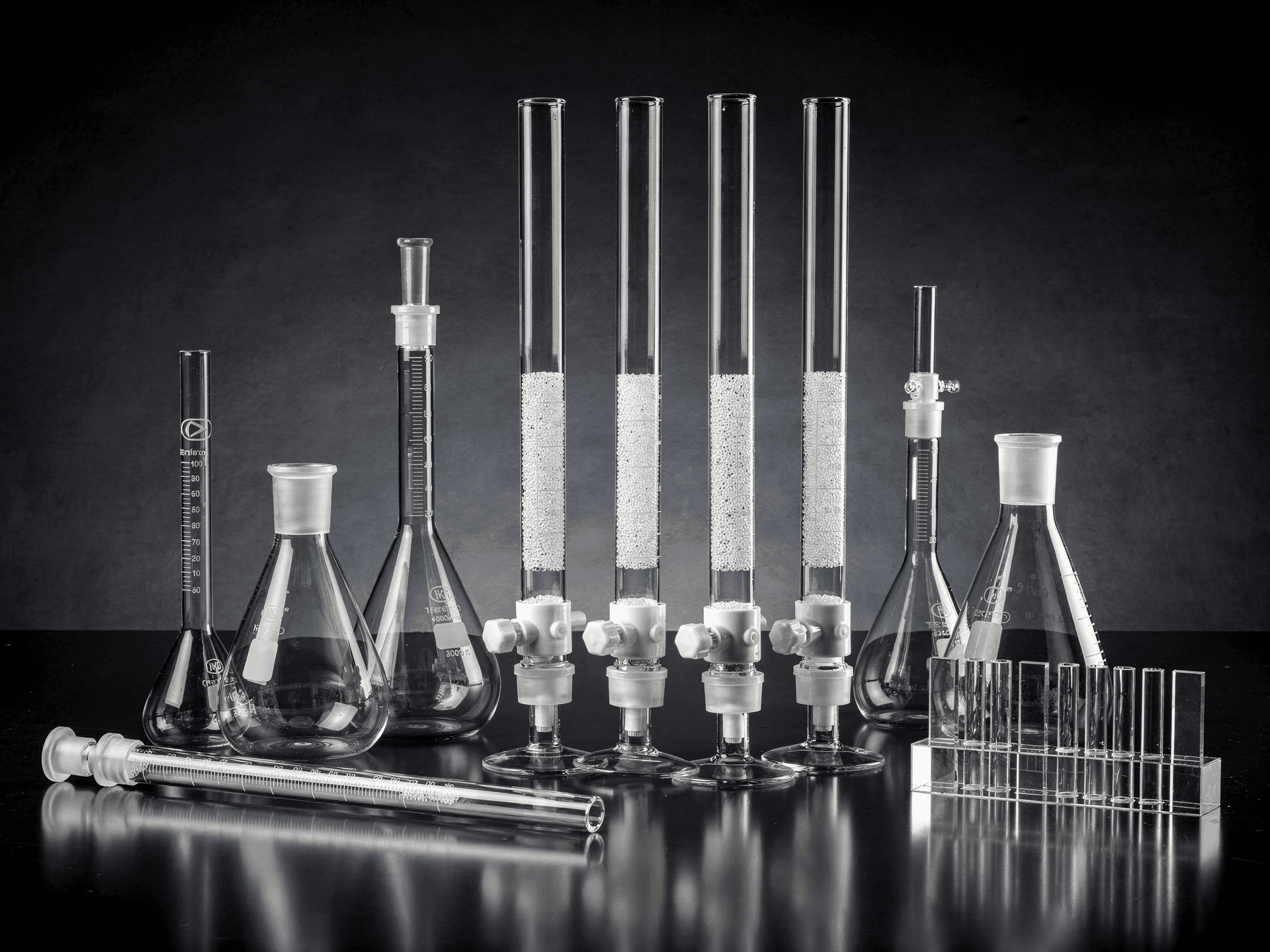

Custom Laboratory Glassware

Bespoke borosilicate and quartz glass apparatus — flasks, beakers, condensers, and custom vessels with ground glass joints, fabricated to your exact specifications and dimensional tolerances.

Abgino crafts bespoke scientific glassware with master precision. From custom laboratory apparatus to intricate research instruments — forged in flame, perfected by hand.

Comprehensive range of scientific glassware across eight specialized categories, each crafted to exacting standards.

Flasks, beakers, condensers, and custom vessels with precision ground glass joints.

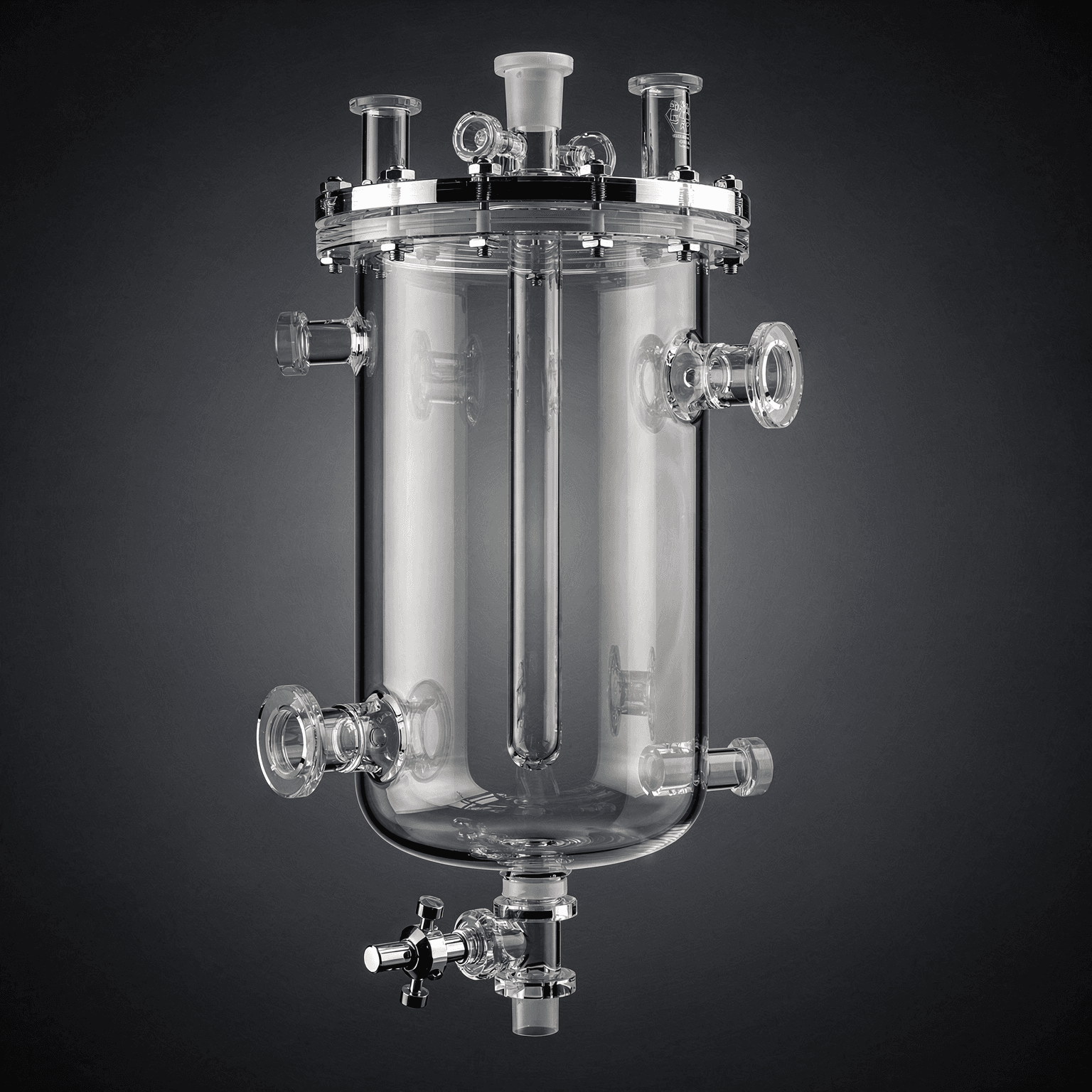

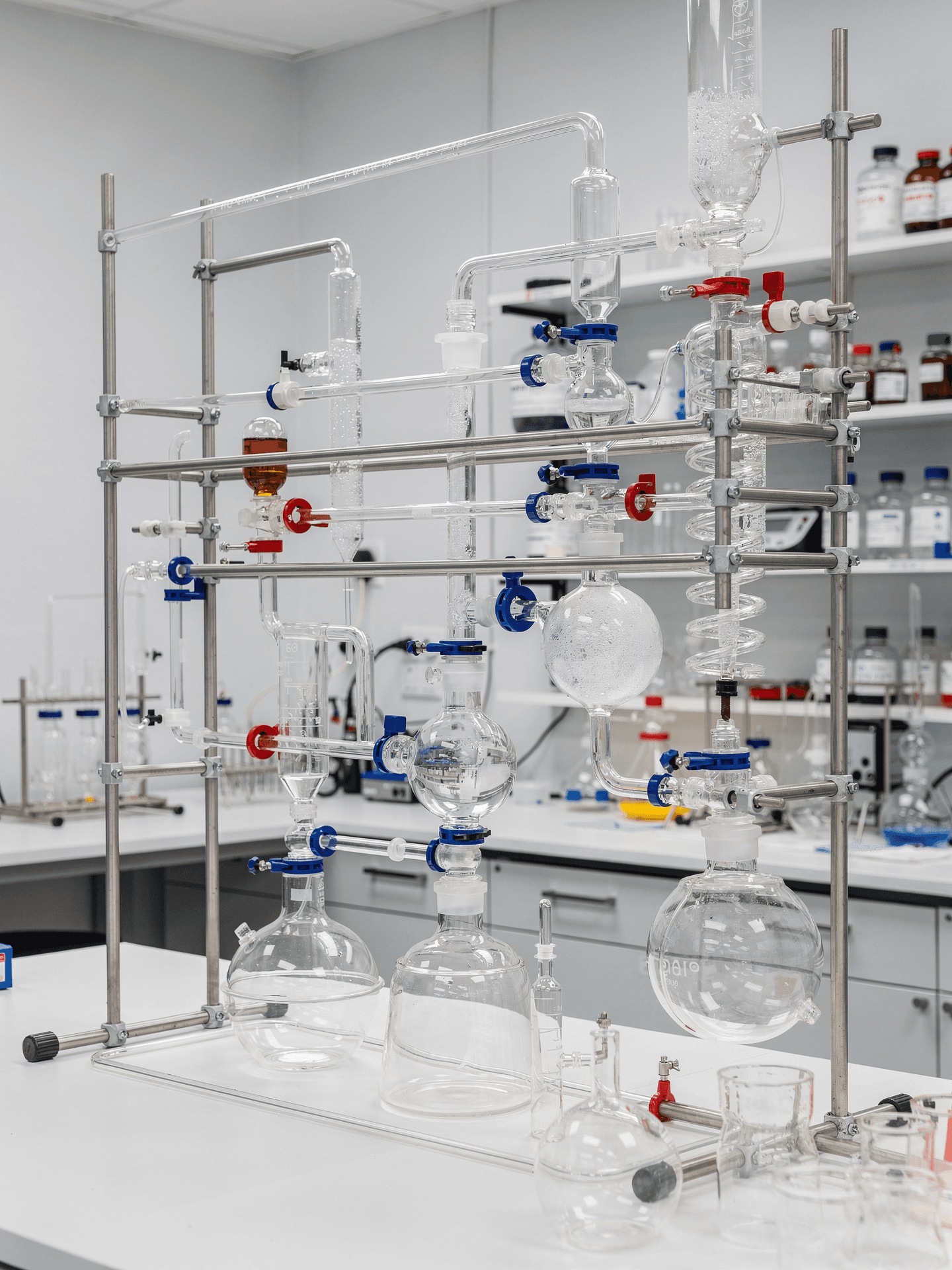

Single-wall and jacketed double-wall glass reactors from 100mL to 200L.

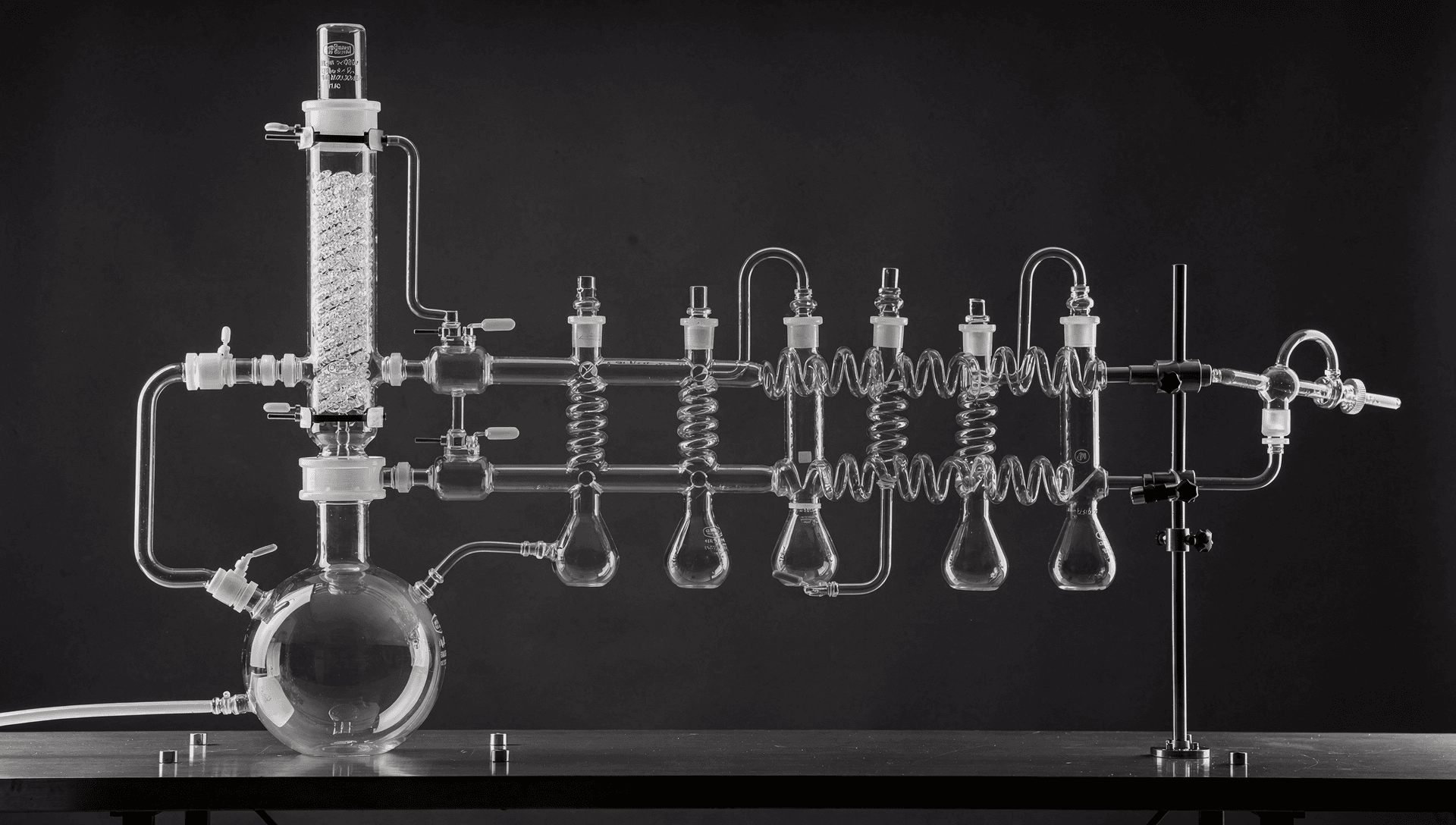

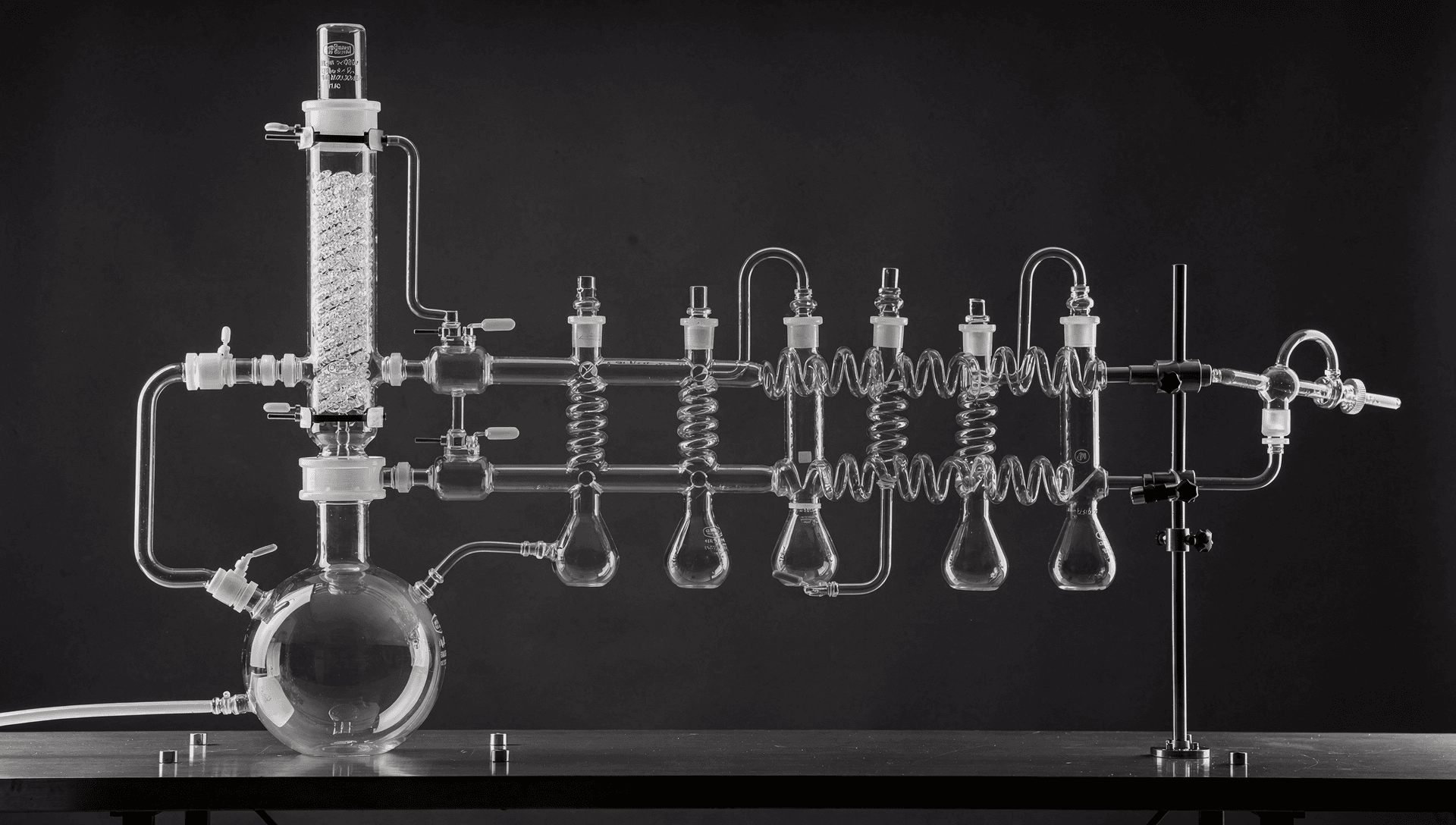

Complete distillation columns, fractional setups, and Soxhlet extractors.

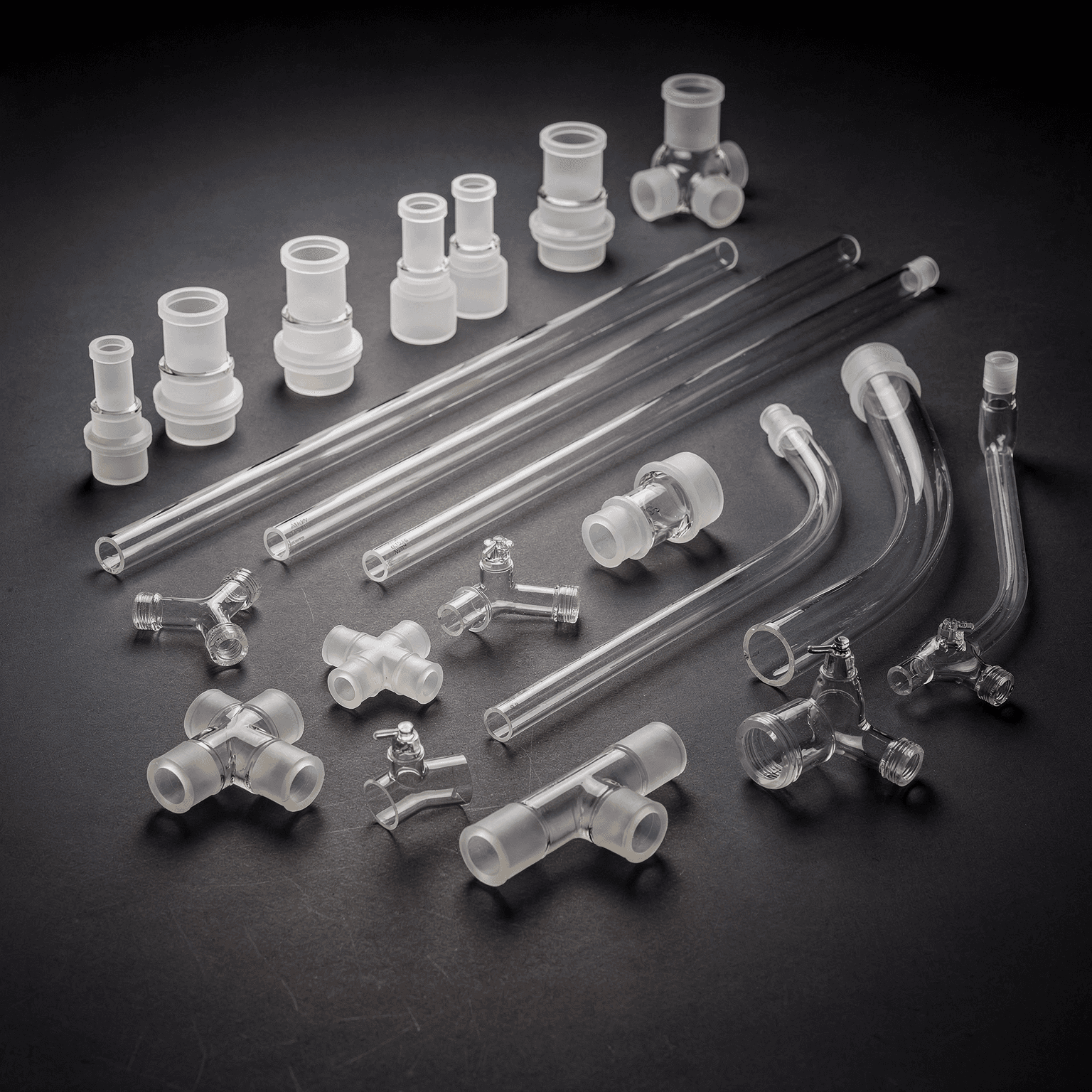

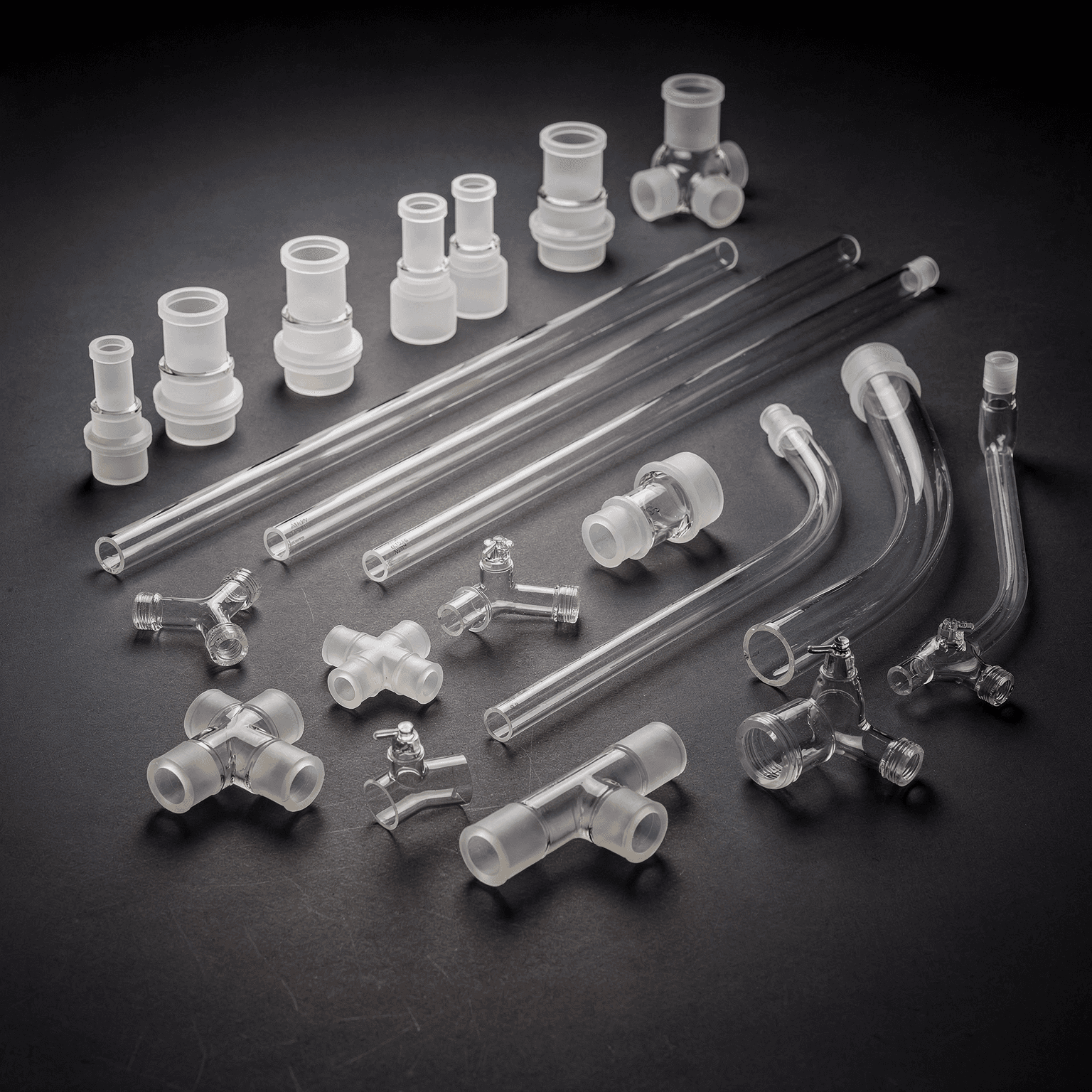

Ground glass joints, stopcocks, adaptors, and tubing connectors.

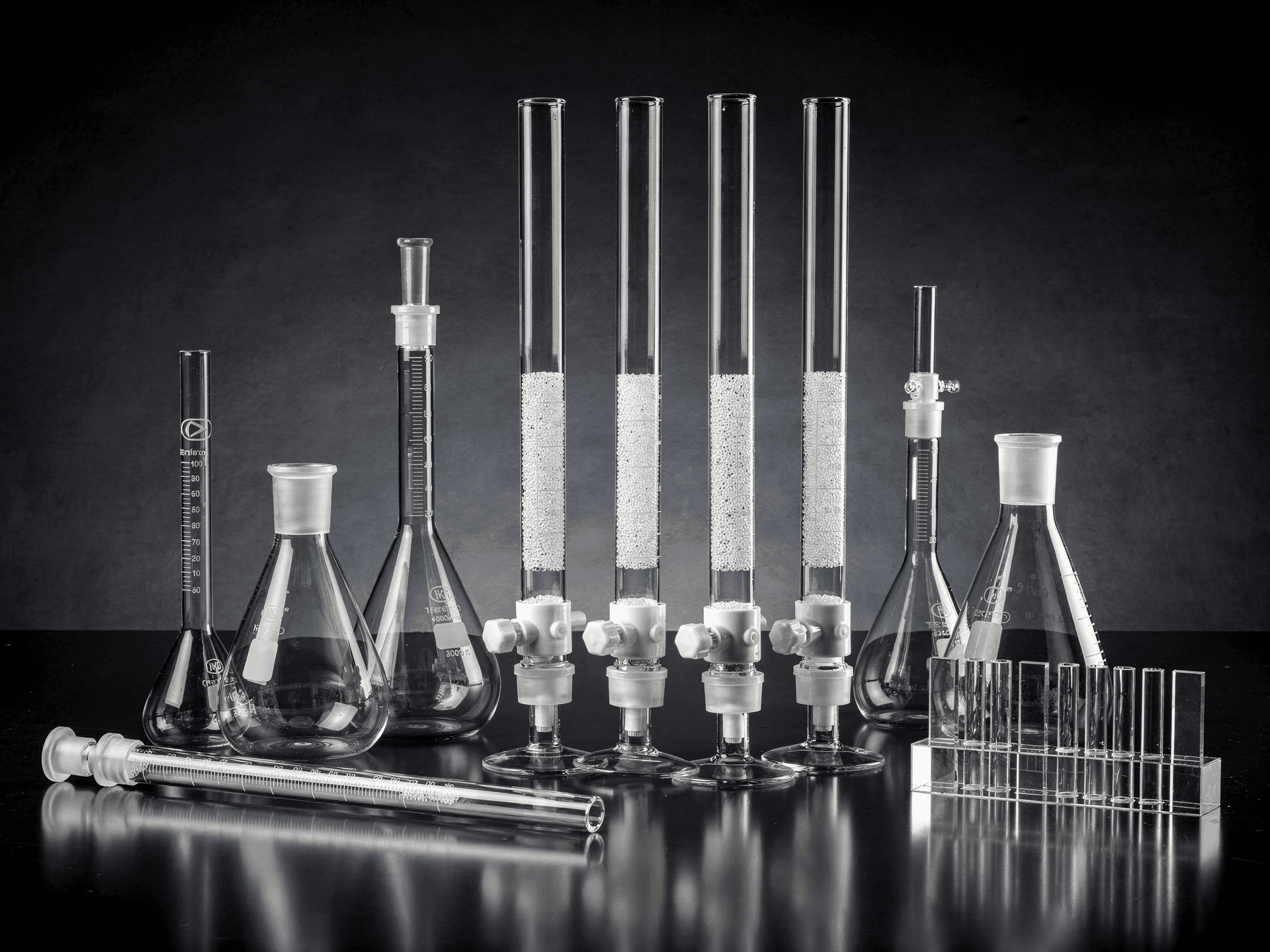

Precision-bore columns with fritted discs and PTFE stopcocks.

GMP-compliant ampoules, vials, and process vessels meeting ISO standards.

Volumetric flasks, pipettes, burettes, and analytical grade instruments.

Filter funnels, extraction apparatus, and gas washing equipment.

From the simplest test tube to complex distillation systems — every piece is hand-crafted to exacting standards.

Conical flask for mixing and titration

Heating, distillation, and reactions

Measuring, mixing, and heating liquids

Holding, mixing, and heating small samples

Precise liquid volume transfer

Cooling vapor back to liquid phase

Filtration and liquid transfer

Accurate volume measurement

From concept to creation, our master glassblowers transform raw borosilicate into precision instruments that advance science.

Bespoke borosilicate and quartz glass apparatus — flasks, beakers, condensers, and custom vessels with ground glass joints, fabricated to your exact specifications and dimensional tolerances.

Single-wall and jacketed double-wall glass reactors from 100mL to 200L. Multi-port tops, temperature jackets, and custom configurations for pharmaceutical synthesis and chemical processing.

Complete distillation columns, fractional distillation setups, Soxhlet extractors, liquid-liquid extraction systems, and gas washing bottles with integral glass filters.

Precision-bore chromatography columns with fritted discs and PTFE stopcocks. Analytical glassware for spectrometry, titration, and quality control applications.

GMP-compliant pharmaceutical glass containers, ampoules, vials, and process vessels. Manufactured to ISO 3585, ASTM E438, and USP Type I borosilicate standards.

Expert repair of cracked, chipped, or broken scientific glassware restoring original specs. Standard 3–5 day turnaround with 24–48 hour emergency rush service for critical equipment.

Understanding glass is the foundation of our craft. Each type offers distinct properties for specific scientific applications.

Our primary material. Exceptional thermal shock resistance up to 500°C, low expansion coefficient, and excellent chemical durability. The gold standard for laboratory glassware.

Ultra-pure fused silica for extreme conditions. Handles temperatures above 1,000°C, transmits UV light, and is virtually chemically inert. Ideal for optical and high-temperature applications.

Cost-effective option for non-critical applications. Good optical clarity and workability. Used for storage containers, slides, and general-purpose labware where thermal stress is minimal.

Every piece follows our meticulous six-step process, refined over 25 years of scientific glassblowing excellence.

We begin with a detailed discussion of your requirements. Our engineers review specifications, tolerances, and intended use to create precise blueprints for your apparatus.

We select the optimal glass type — borosilicate, quartz, or specialty glass — based on thermal requirements, chemical resistance, and optical clarity needed for your application.

Our master glassblowers work at temperatures exceeding 2,200°F, shaping molten glass with hand tools, lathes, and specialized torches. Each piece is formed with decades of muscle memory.

Finished pieces undergo controlled cooling in precision kilns. This critical process removes internal stresses, ensuring durability and resistance to thermal shock during use.

Every piece undergoes rigorous testing — polarimetric stress analysis, dimensional verification, leak testing, and visual inspection under specialized lighting to ensure perfection.

Carefully packaged and shipped with full documentation. We provide ongoing support, maintenance guidance, and are always ready for modifications or replacements.

Certifications & Standards

A curated collection of our finest scientific glasswork. Each piece represents hours of meticulous craftsmanship.

“Abgino crafted a custom vacuum distillation system that exceeded our specifications. Their attention to tolerances and joint quality is unmatched.”

“We've been working with Abgino for over a decade. Their repair turnaround is exceptional, and their ability to replicate discontinued apparatus has saved our production timeline multiple times.”

“The prototype-to-production process with Abgino is seamless. They understood our reactor requirements intuitively and delivered vessels with sub-millimeter precision.”

Everything you need to know about our scientific glassblowing services, materials, and process.

We specialize in borosilicate glass (Pyrex-type, ASTM E438 Type I Class A) and quartz (fused silica) glass. Borosilicate offers excellent chemical resistance and thermal shock resistance up to 500°C. Quartz handles temperatures exceeding 1,000°C and provides superior UV transparency for optical applications.

Standard custom fabrication takes 2–4 weeks depending on complexity. Simple modifications and repairs are typically completed within 3–5 business days. For critical equipment, we offer emergency rush service with 24–48 hour turnaround at an additional fee.

Yes. We repair cracked, chipped, or broken scientific glassware including flasks, condensers, reactors, and custom apparatus. Our repairs restore original specifications and dimensional tolerances.

Abgino is ISO 9001:2015 certified. Our glassware meets ASTM E438, ISO 3585, and USP Type I borosilicate standards. Pharmaceutical glassware is fabricated under GMP-compliant protocols. All pieces undergo polarimetric stress analysis and dimensional verification.

Yes. We design and fabricate single-wall and jacketed double-wall glass reactors in volumes from 100mL to 200L. Systems include multi-port tops, temperature control jackets, and custom port configurations.

We serve pharmaceutical companies, chemical manufacturers, university research labs, petrochemical facilities, biotechnology firms, environmental testing labs, and government research institutions.

Borosilicate glass has a low thermal expansion coefficient and resists thermal shock up to 500°C at lower cost. Quartz glass handles temperatures above 1,000°C, transmits UV light, and is virtually chemically inert — but costs significantly more.

Yes. We ship worldwide with custom protective packaging designed for fragile scientific glassware. All shipments include full insurance and tracking.

Whether you need a single custom piece or a full production run, we're ready to bring your vision to life.

Tehran, Iran

View on Google Maps